We bought the top 3D printers available on the consumer market and put them through a grueling series of standardized tests and comparisons to crown some winners. Ultimately, we narrowed down four of the most important categories of evaluation to capture the widest range of aspects a hobbyist or average consumer will be interested in. Be sure to review our complete breakdown to see which printers came out on top and which are the best bang for your buck after all the testing is said and done.

Print Quality

The first and most important rating metric we use is Print Quality. An extensive search was conducted to find print models that would directly assess different aspects of a print in an objective manner. Care was taken to ensure all prints were produced with normalized settings (0.4mm nozzles and 0.25mm layer heights) and with as close to out-of-the-box settings as possible. A panel of testers, experts, and others with varied fields of experience then blindly rated and scored each print.

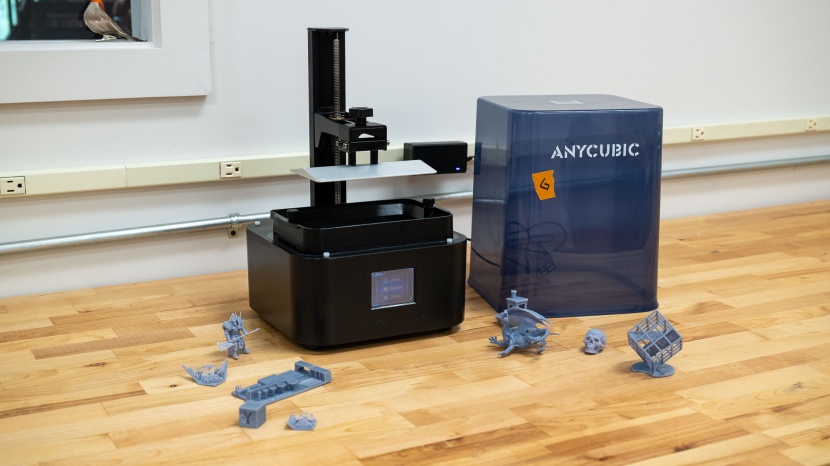

We will note that much of our testing focuses on the most common printer type, FDM (Fused Deposition Modeling, also known as FFF - Fused filament fabrication). These types of printers melt a plastic filament rolled on a spool and precisely deposit a running bead on ever-growing layers to build a 3D shape from the ground up. Several UV-cured resin-type (aka stereolithography, or SLA) printers were also tested, which have less popularity in the hobbyist market but are generally well regarded and can be useful in the right time and place. These printers work by selectively exposing a powerful light through a vat of resin, progressively curing a 3D shape in additive layers from the top down.

XYZ Calibration Cube

Flat surfaces often reveal defects better than more complex geometry, and known dimensions can show how accurately a printer can execute parts with a critical fit. Sharp corners can reveal slop in the physical belts and motors, and inset lettering helps give an idea of resolution at that scale. Any wave in the flat sections can reveal extrusion concerns with controlling wall thickness, and rounded or protruding corners could indicate a slight setting adjustment needs to be made in the software prep.

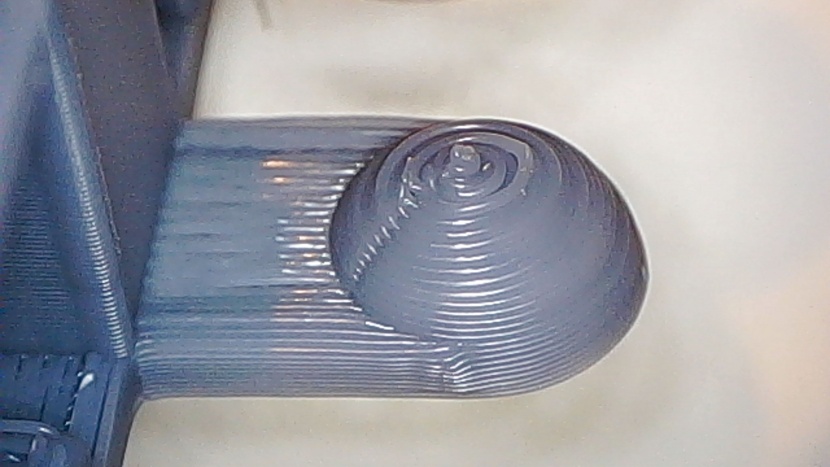

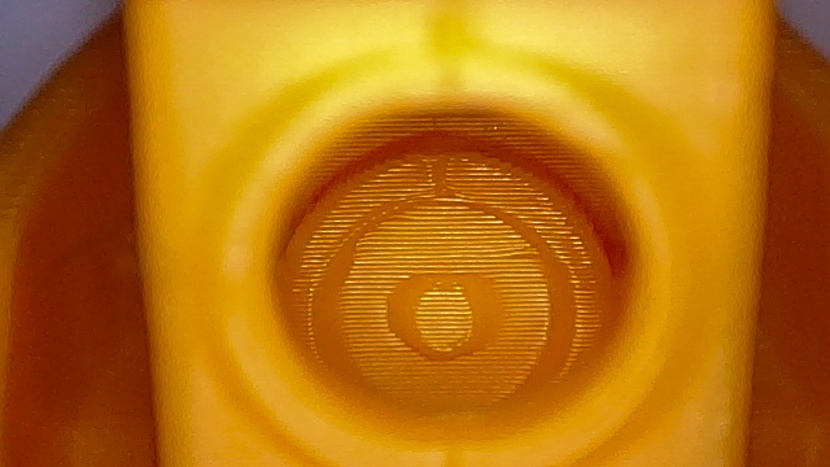

Vase

This decorative vase is printed using a special print setting (called 'Vase Mode'), where a single wall thickness prints a continuous spiral, effectively making a thin shell. This aims to reveal extrusion consistency issues, as any tiny gaps between layers will be unmasked with a full of water, and layer thickness consistency is apparent by holding the print up to a light.

Lattice Skull

Resin printers can't print in a continuous line, as they expose entire layers at once. Instead of a Vase test with them, we run a skull with an intricate lattice to reveal the cleanliness of connection points at every conceivable angle.

Z-tower

Meant to test a printer's stability in the Z-direction (vertical), the Z-tower is simply that - a tall tower with flat sides. Any slight wobble will show up as waves on the surface, and any drift in the X or Y directions will be clear as day. As with the cube, we scored based on the smoothness of the sides and the sharpness of the corners.

Bridging & Overhangs

FDM printers print in the open air, subject to the same forces of gravity as the rest of us. Printers, understandably, struggle to print over nothing when gaps, spans, and steep angles are presented. Prints are either cleverly placed in a way on the build plate to avoid issues as much as possible, or, more commonly, they are printed with a series of computer-generated support structures. This model is a stress test, intentionally subjecting printers to wide, unsupported spans and a progressively tough angle of overhang. Supports can leave surface quality issues at the point of contact, so this test is useful in revealing which printers can get away with the fewest number of supports necessary. This test is not done with resin printers, as they are supported by the resin and not subject to the same gravity forces.

Moving Parts and Clearances

A smart design originally created by Industrial Designer Angus Deveson is meant to show precision in depositing layers for any print that will have moving parts. If progressively smaller clearances around the part resolve correctly, a basic fidget spinner toy will be revealed.

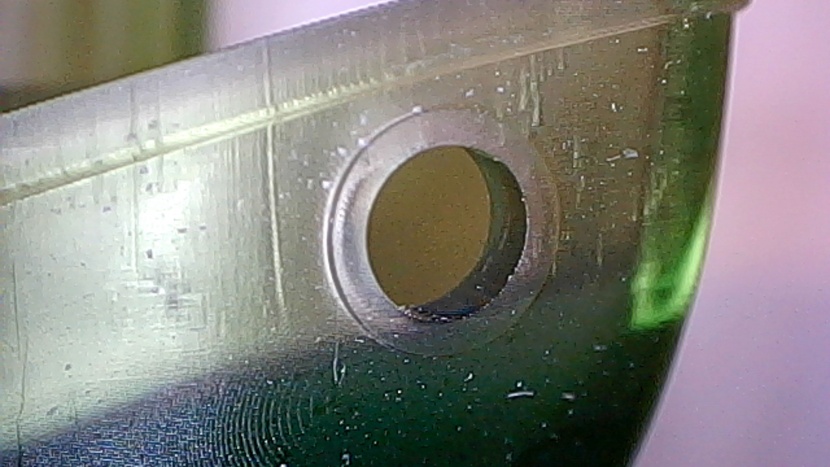

Coin Fit

Chosen to check for dimensional accuracy a little more directly than the above cube, this simple frame is printed at the exact height of a US Nickel, with a hole the precise diameter. Evaluation is obviously done by checking the fit, and scores are given based on how in or out of spec the piece ends up.

Support Removal

The follow-up test to the bridging obstacle course is the creation of a small part intentionally designed to force the maximum amount of supports to be generated onto differently shaped surfaces and at several angles. Scores are given based on how easily they break away from the main print and the surface quality at the connection sites. A properly dialed-in support setting should just barely make contact with the main print while providing just enough support to not interrupt the model's geometry. They should break away easily with one's fingers and leave a relatively pristine surface.

Benchy

Also nicknamed as "The jolly 3D printing torture-test by CreativeTools.se", Benchy is a little cartoon tugboat. It has grown in reputation over the years to become an industry standard of sorts, commonly used by hobbyists and professionals alike to diagnose a plethora of common issues. As such, it wasn't chosen to test a specific attribute of a print model's execution but instead as a comment on the overall quality. This model has overhanging sections, fine details, bridging, and thin cylinders. In essence, we were looking for clean prints — no glaring defects, a smooth hull, round portholes, and just a generally nice-looking boat.

Ease of Use

While the team spends much of its meticulous evaluation effort on the print quality metric, Ease of Use is almost as important, accounting for 30% of the final score. Each printer is subject to a series of hardware and software checks, built and timed, poked and prodded, beds leveled, and their temperature measured.

Initial Setup

Build time is measured from cracking open the box to running a first test print. Notes are taken on the ease of manual interpretation, the number of parts and pieces handled, and the ease and effectiveness of calibration.

Software/ Slicer

Most printers come with recommended software (also known as slicers, as they will figuratively slice your print model and convert it to g-code that the printer can run), usually released under the same brand. Third-party programs are commonly used and are largely universal, but experienced users will tend to have their preferred option. This is where a 3D model is prepped and exported to be run, with a multitude of settings and adjustments to be made. We want to use the recommended option for each printer whenever a manufacturer makes that assertion to capture the full experience a buyer may have with a product and brand. Scores are given based on ease of use and UX/UI sophistication.

Connection Type, Interface

Moving your print from computer to printer can be done via wifi, direct cable connection, or transferring a file with an SD card or flash drive. App support is also considered. We look for slow or glitchy connections and anything else that jumps out, good or bad. Each machine will have a unique interface to choose and run your prints, load filaments, and change settings. We judge each by clarity and ease of navigation.

Bed Temperature

A relatively new sub-metric in our testing strategy, measuring the pattern and consistency of a heat signature of a printer's heated bed is a good indication of the engineering care taken and of how well prints will adhere. We are mainly looking for an evenness of heat provided and to see that it covers the entire surface. This directly contributes to the ease of using a printer, as print warping and adhesion issues are dramatically decreased by using a heated bed.

Print Capabilities

This metric — making up 20% of the total score — covers a diverse set of attributes. We're mostly comparing the major specifications between printers and confirming that the manufacturer's claims are accurate.

Build Volume

This is an obvious, important consideration for many consumers. A larger build volume means more freedom in what can be designed and produced. Larger volumes do directly mean a printer is more 'capable,' but scores were more affected by how close our real-world print dimensions measured were to the MFG claims. Not every printer is capable of meeting these claims, and they are dinged accordingly.

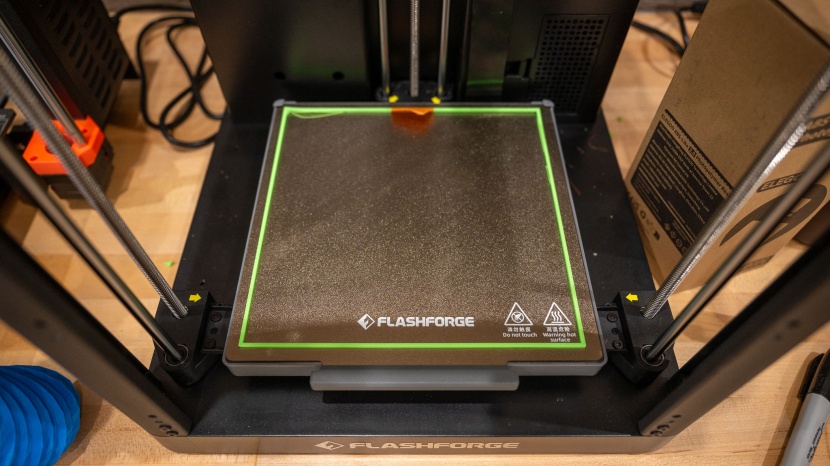

Build Plate Tech

The build plate, or print bed, is the surface upon which a print is built. Though we covered the heating elements in the last metric, other advancements have been made in this arena. Certain textures and coatings, and removable, flexible top plates are all exceptionally helpful and contribute to a print's success.

Max Extruder Temp, Screen Resolution, and Material Capabilities

On the FDM side, specialty and exotic filaments are being released all the time and gaining in popularity. Extruders capable of higher temperatures are needed to melt these materials, and only some products will be capable. A brand will often recommend a certain set of materials and recommend against others.

Resin printers don't have the same variety of material choices. These days, they are mainly limited to water-washable and plant-based materials in addition to the standard resins, which are largely the same between brands. Instead of extruder temp, the spec we're most interested in here is the screen resolution, which directly affects the level of detail achievable in a print.

Bells and Whistles

More of an unofficial sub-metric, there are printers that include certain upgrades and add-ons that are important and useful enough we have to make mention of them. Features like built-in cameras can help a user monitor print progress remotely and stop a print in the event of a failure without being physically present. Multicolor prints are starting to become viable, using multiple filament rolls that can be purged and changed automatically throughout a build, and that feature alone may push a consumer to buy over a competitor. Most other considerations here are in the realm of engineering improvements — an updated algorithm to curtail wobble by 5% or improved fan and cooling control.

Support

Our final metric accounts for the residual 10% of the score. We test customer support options and effectiveness by calling in a pretend troubleshooting issue. Manuals, video support online, and other resources specific to each printer are evaluated, and warranties are sized up. This aspect of a product category so inherently finicky and rapidly changing is often overlooked but is important in its own right.

Conclusion

The 3D printer market is rapidly changing and improving in this highly competitive space. Our test procedures across all metrics are designed to be as future-proof as possible, ensuring long-term reliability in comparing the proverbial 'apples-to-apples' among product releases years from now as new brands and technologies emerge.