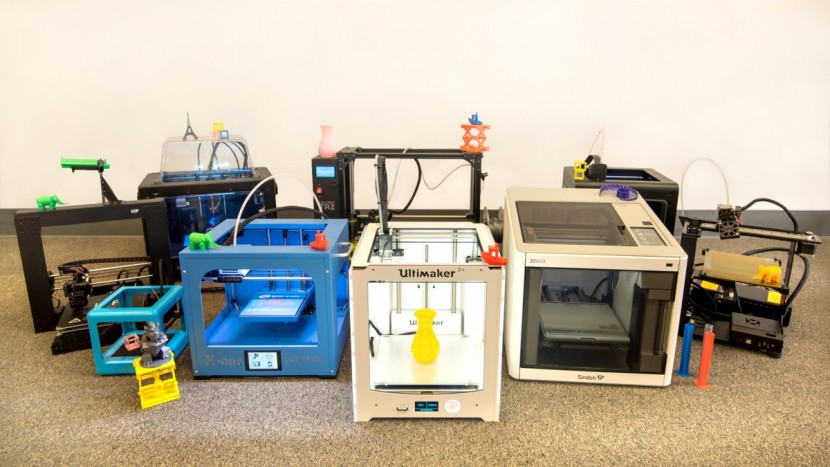

Three-dimensional printing at the consumer/hobbyist level has exploded in popularity since the original MakerBot started shipping in 2009, but only in the last five or so years have truly polished products geared toward beginners come on market. This is an incredibly exciting time to be in the industry, watching rapid technological advancements release year-over-year while enjoying affordable, high-quality machines in the present. But how do you begin to sort through the vast ocean of available choices? Byrunrelying on GearLab's hands on testing, of course. Beginners and experienced users alike will find solace in our hallowed halls as rapid change continues to move the needle. For more information on specific models in our tested lineup, take a look at our comprehensive 3D printer review and our breakdown of how we designed our testing procedure.

What is 3D Printing?

3D printing at its core is additive manufacturing. A digital model or object is converted by a computer to hundreds or thousands of thin slices, which a printer then interprets and precisely deposits in layers of material, one on top of another until a physical representation of that model is made. The machines, technologies, methods, and materials that can do this vary wildly, but the core concept is the same for each.

The focus for much of the industry's history has been squarely on the commercial and industrial spaces. There are shapes and models able to be made with 3D printing which are not possible, or are otherwise prohibitively expensive, difficult, or time-consuming to make in other ways. It allows for creatively intricate objects to become reality where they were once impossible.

Engineers, scientists, and designers all use 3D printers to stay on the cutting edge. They can make prototypes and client presentation models in hours and at a fraction of the cost of previous techniques.

Why Buy a 3D Printer

At the hobbyist level, where GearLab focuses our testing and write-ups, printers these days are used to make toys, tabletop gaming figurines, custom brackets, product modifications around the house, tool jigs/guides/templates, and real-world representations of one's digital art. Students and designers can now create from the comfort of their homes. In most cases, materials for these products are affordable, and a model the size of a football, for example, can be made for about $5.

You may find value in printing your child's favorite Disney-licensed toy of the month for pennies on the dollar. Maybe you or a favorite Dungeon Master in your life would love a Mt. Doom dice tower or an army of Orc figurines for your next quest. Or you'd like to make a custom headphones holder to clip on your desk, a beautiful lampshade you saw on TikTok or a Hello Kitty cookie cutter. The possibilities are endless.

Types of 3D Printers

You should know there are two main types (i.e. technologies) of consumer-level printers on the market today: FDM, and Resin. The right one for you will largely depend on the level of detail you require.

FDM Printers

The most common, easiest to use, and feature-rich printer type manufactured and purchased today is FDM — Fused Deposition Model. FDM is a trademarked acronym, but it is the most commonly used term to describe the technology of Fused Filament Fabrication (FFF). An FDM printer uses a spool of thermoplastic material, commonly PLA (polylactic acid), melts it in a moving head (the extruder assembly), and deposits it layer by layer into a hollow representation of a digital model.

We would argue the major reason FDM technology dominates the landscape is the fact it is (relatively) user-friendly. We say 'relatively' because there is still quite the learning curve to the digital modeling and model-creation side of things — though these programs are also becoming dramatically easier to learn and use — as well as a learning curve to taking a model and prepping it for print. We'll delve into those points a little later. But, it gets much easier from the printing stage onward. In this regard, FDM wins that battle over Resin. In many cases, when a print is done, it can simply be popped off the build plate. If settings are dialed in well enough, little to no post-processing will be needed.

We'll also mention that there are more software settings and adjustments to be tweaked on FDM vs. Resin printers. In this way, FDM lends itself to experimentation. FDM also tends to be where we see more hardware innovation, like the addition of cameras for remote print monitoring, and material innovation, like TPU filaments, which are flexible.

Resin Printers

The other side of the coin is a fundamentally different technology, colloquially known as 'resin' printing, but more professionally known as SLA (Stereolithography, AKA vat photopolymerization, optical fabrication, and a myriad of other terms). Essentially, SLA prints are created through a powerful light or laser curing layers of photosensitive resin. There are a few ways this can be done, but in most consumer-grade machines, the light is selectively blocked by a monochrome LCD screen, which exposes an entire layer of your print at once.

The main thing to know is that resin/SLA prints can be exceptionally detailed. Intricate parts with resolutions as low as 18μm (about 1/6 the width of a human hair!) are possible with resin printers well under $200 today. This blows plenty of FDM printers out of the water, but not always. What you do with that level of minutiae is up to you.

This resolution advantage comes with a major tradeoff. The resin itself is goopy, sticky, and smelly. Precautions in handling, printing, cleaning, and especially post-processing are also needed. After a print is complete, it must be wiped clean of uncured resin, thoroughly washed, and then UV-cured to further strengthen the material.

Resin/SLA machines themselves are usually a little cheaper than FDM, but the resin is more expensive. Most users will also choose to buy separate washing and curing chambers. They also tend to have smaller build volumes than FDM, but the gap is closing.

A Note on Slicers

Slicing programs are essentially the software that turns your 3D model into code that the 3D printer can read and execute. Popular options have traditionally been fairly open source, and many can prep files for both FDM and SLA printers. Do know there is a learning curve involved in dialing in your printer and knowing how to truly optimize it. These days, most major printer brands have their own slicer and even a support app, and many of them have made great strides in the UX/UI and understandability and usability for novice users.

New to 3D Printing? Prioritize Ease of Use

Affordable desktop printers have, until recently, not been especially friendly to novice users. Resin printers still require labor-intensive print processing, but FDM has historically had about 10x more issues that could arise at any given stage of the process. Resin printers still have some ways to go, but for now, FDM is the clear winner in ease-of-use.

Upgrades, Advanced Features, and Other Considerations

With the guesswork and required tinkering being slowly phased out with the new wave of polished product offerings, consumers can start focusing less on just getting their printer to run well and more on buying the product with the exact bells and whistles tailored for their personal whims.

Improved Max Extruder Temps

We're seeing the market slowly add specialty and exotic filaments on the FDM side. These materials can give your prints flexibility (TPU), a sandable wood-like look (wood-infused PLA with sawdust in it), or extra strength with tiny carbon fiber strands added (PETG-CF), among other attributes.

The catch is these filaments often have higher melting and flow temperatures. Some printers are starting to specifically chase this segment of the market by raising their maximum extruder temps.

Resin printers don't currently have the same kind of specialty material library, but keep an eye on this as innovation continues to accelerate in this space.

Cameras, Time-lapses, and Remote Monitoring

We're seeing built-in cameras start to become more common, especially on the FDM side. Some big, intricate, or heavily infilled prints will take 24 hours or longer to complete, and at some point, we all have to sleep or go to work. These cameras allow one to monitor print progress remotely through an app, and in some cases, an AI can be used to automatically detect print failures and stop a print before too much material is wasted or, worse, damage to the extruder becomes unrepairable.

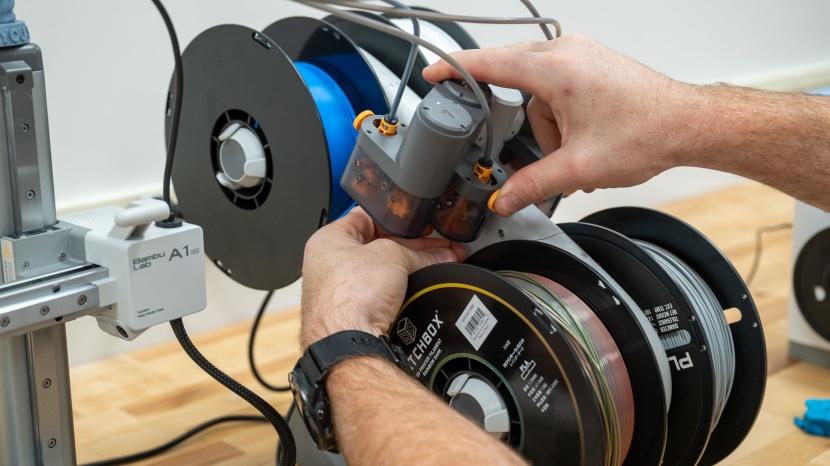

Multicolor Printing

Multicolor printing is nigh impossible with resin printers at the moment, but with FDM, it is starting to become a relatively impactful feature on some products that integrate it. Painting a print is labor intensive after the fact, but with multiple colors made during the print phase itself, users are suddenly able to print products that are Etsy-worthy with minimal post-processing and time involvement.

Unfortunately, this process tends to be wasteful and takes much longer than one-color prints, but we expect this area to rapidly improve in the near future as well.

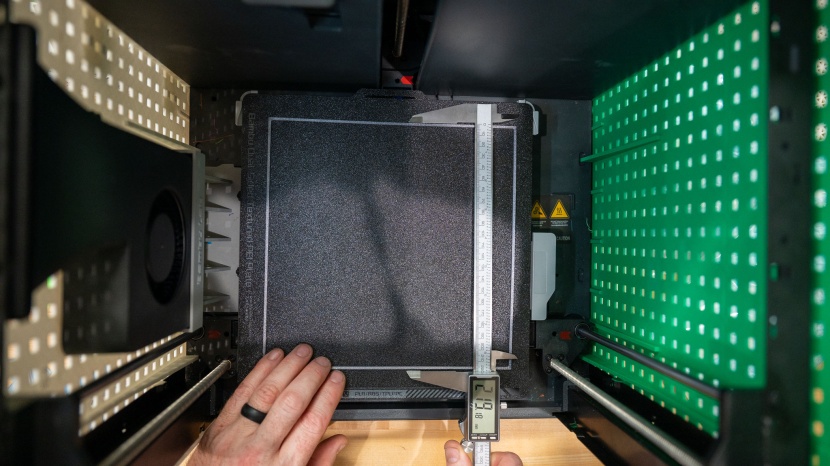

Build Volume

With recent engineering improvements, we're seeing printers with larger build volumes become more common. Having the option to print larger items, say a helmet, in one go is now possible. Many software programs allow users to split large models into sections for easy printing with smaller machines. Models that have at least an 8"x8"x8" build area will be able to print the vast majority of models without splitting, and this is a good, middle-of-the-road build envelope to start with.

Value

If your main focus is on finding an affordable, all-around great-performing printer, you'll want to look specifically at our Best Buy award-winning products. But, there are lots of ways to assign value to a product in a space as diverse as 3D printing. You'll want to look at scores from the categories that interest you most or look specifically at options that have a particular feature you're looking for.

Online File Repositories

One of the easiest ways to find things to print is to download them from the internet. Designers upload their models, and all one needs to do is download their favorite and run it through their slicer program of choice. In some cases, a printer can be running a print less than 10 minutes after finding it online.

Some popular sites include Thingiverse, Pinshape, yeggi, Thangs, and Printables. These sites offer tons of files for free. In addition to offering files, these sites will occasionally host contests and challenges with prizes.

Design Your Own

Are you bored of printing other designers' work, or can't find what you are looking for? Then, it may be time to take up drawing your own using a CAD (Computer Aided Design) program. To start, the unfortunate truth is professional CAD programs can cost tens of thousands of dollars, and proficient modeling can take years to learn. That said, there are a handful of free or cheaper programs that aren't too difficult to learn, such as Sketchup and TinkerCAD. The next step up would be programs like Blender and Fusion360 — these programs can be intimidating for the novice but are much more powerful and can largely be learned through online tutorials on YouTube and elsewhere.

3D Scanning/Photogrammetry

The final method to create a 3D file is by scanning a real-world object, using a 3D scanner (or a 3D scanning attachment for your mobile device), or through photogrammetry — a process for combining many 2D photos of an object into a 3D printable file. However, this functionality is still mainly in the realm of professional-level products and skills. Reliable, high-quality consumer-grade scanners are a little hard to come by, and the options that do exist have mixed results and can represent a significant investment, ranging from a few hundred bucks to several thousand. Photogrammetry works well enough with simple objects, and a fair number of apps and programs are able to accomplish this task.

Conclusion

Beyond this, your best bet is to delve head first into our complete tested 3D printer review for a taste of what is current and available on the market today or peruse our How We Test article for a comprehensive look at our testing and ranking procedures. The right product is out there for you.