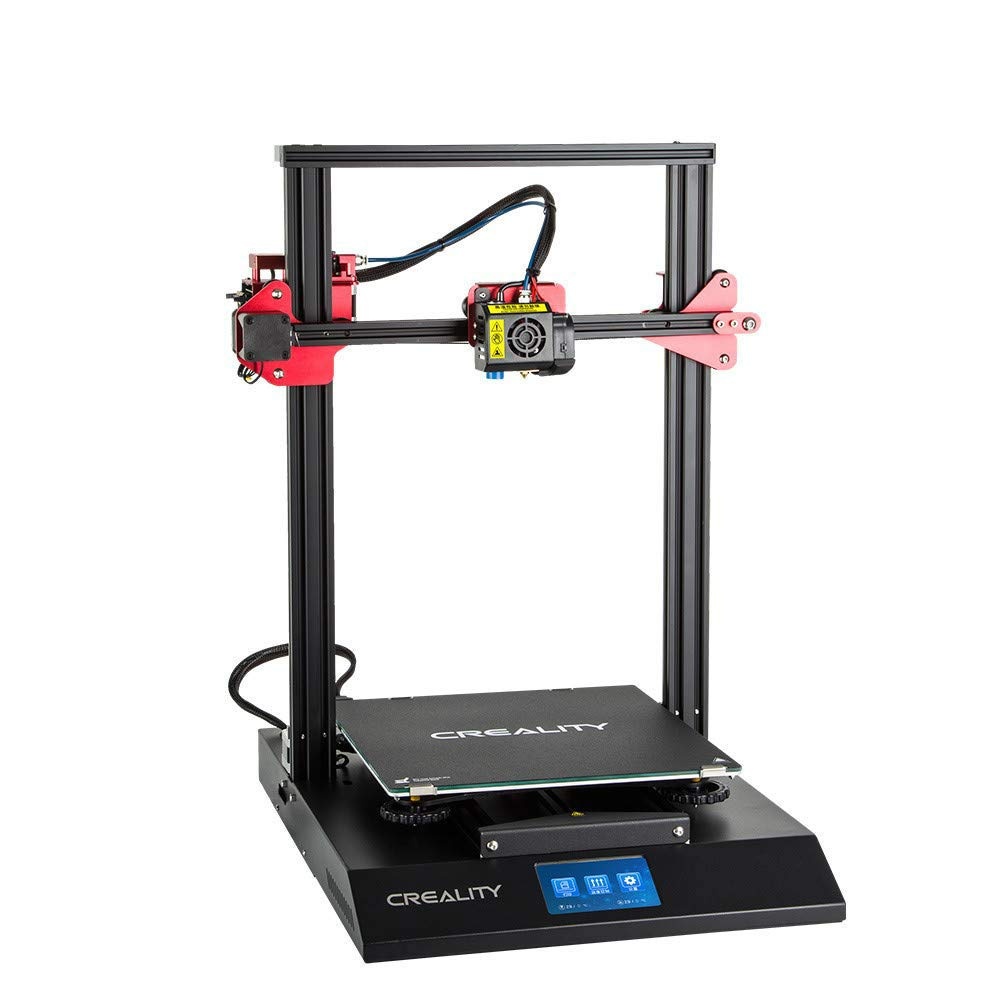

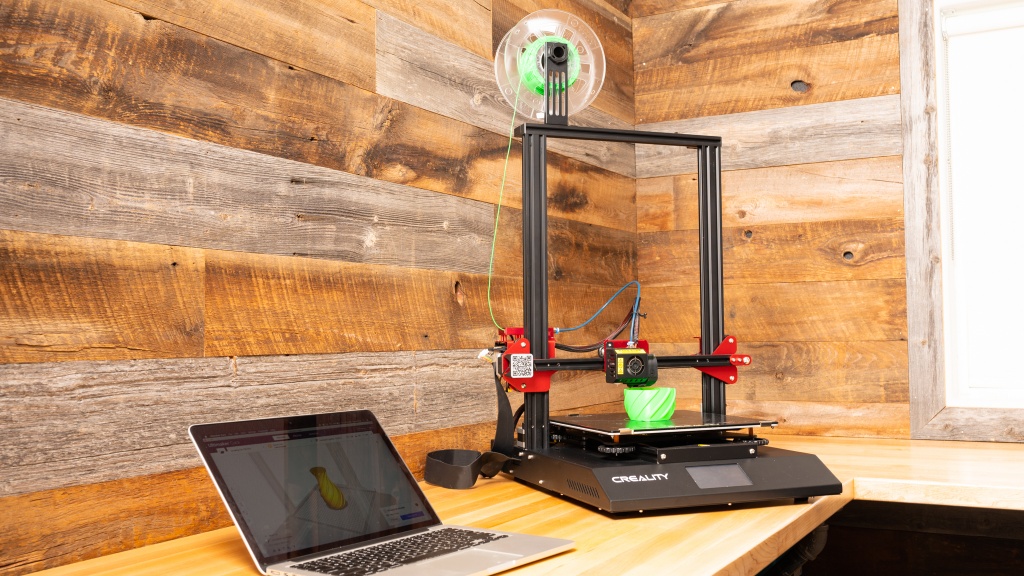

Creality 3D CR-10S Pro V2 Review

Our Verdict

Our Analysis and Test Results

While the initial assembly and so-so customer support can be a bit off-putting for beginners, this printer is one of the most user-friendly we have seen once it is all set up, having things like power loss detection, filament sensors, and even an automated bed leveling process.

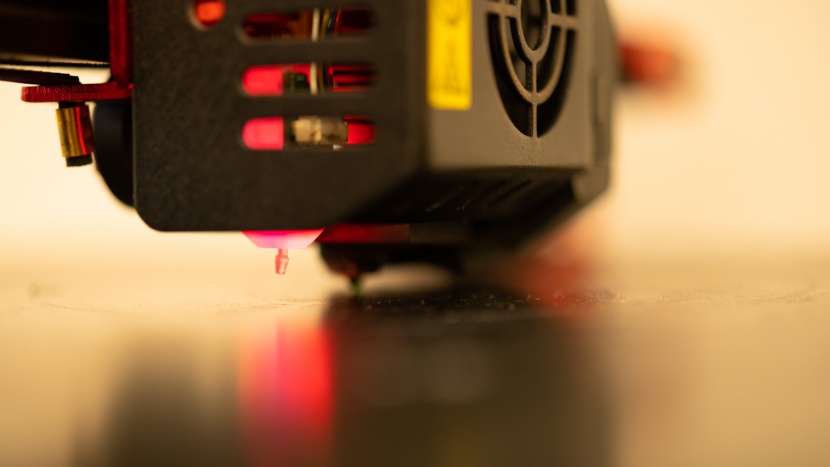

Print Quality

Our print quality metric is the most significant to the overall score for each 3D printer, accounting for 40% of the total points. For the FFF printers, we made a series of evaluation prints in both PLA and ABS and then had a panel of judges compare them side-by-side. These prints were selected to compare and test the performance of each printer with various geometries, such as bridges, overhangs, and thin features.

The first of our evaluation prints is a common calibration/torture test known as a 3D benchy. This little tugboat has it all when it comes to evaluating prints, having text, fine details, overhangs, and bridges. The Creality CR-10S Pro V2 did a great job with the PLA version, creating a very smooth hull and handling the difficult geometry with aplomb. However, the lettering on the first layer was a bit distorted. The ABS version didn't come out as well, with enough layer separation that the roof easily detached.

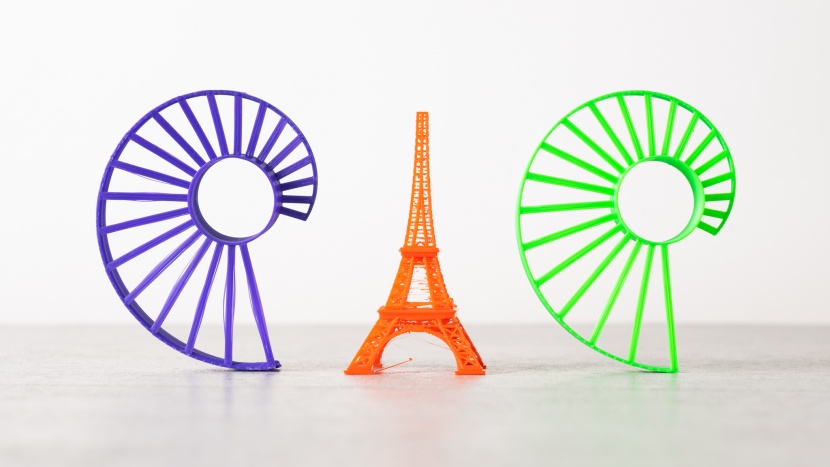

Next, we printed a bridging torture test and a model of the Eiffel Tower. The Creality CR-10S Pro V2 did a fantastic job in PLA with the bridges, with only a few strings dangling on the longest spans but failed to impress with its ABS version or either Eiffel Tower. The ABS bridging test had all sorts of warping and layer separation, while the PLA Eiffel Tower lost a lot of detail and had tons of strings. We never got an ABS version to even print completely.

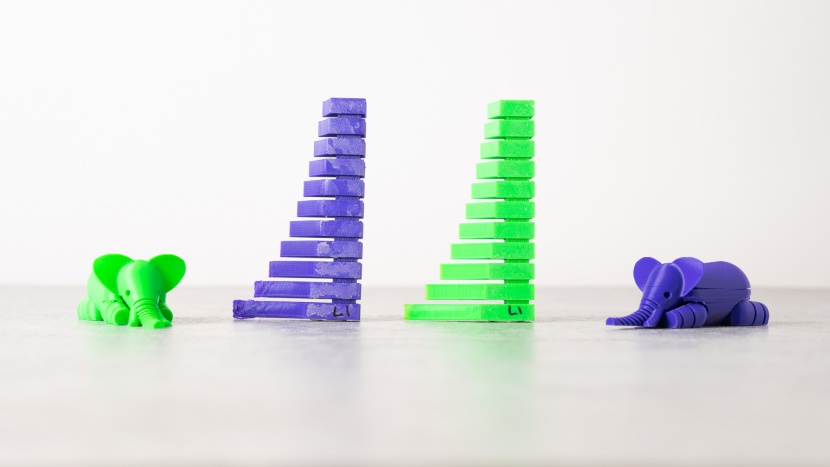

Next, we made an articulated elephant, an overhang test, and a nickel test with each printer. The overhang test has a series of progressively steeper overhangs — all printed support free — with the majority of the score determined by the surface finish of the overhanging face. The nickel test is a flat rectangle with a hole cut out that should perfectly fit a nickel. The Creality CR-10S Pro V2 didn't do great in this test, with a visible gap around the nickel. It did much better in the overhang test, with the PLA version coming out essentially perfect. It did have a slight defect on the largest overhang but overall did an amazing job. The ABS version did come out a little deformed from where it warped, exacerbated on any of the overhangs steeper than 40 degrees. The print-in-place articulated elephant came out great as well — at least in PLA. It moves freely and only had some slight surface finish issues on the overhanging areas. The ABS version articulated fine as well but did have some significant layer separation.

A pair of fairly difficult prints followed but the Creality CR-10S Pro V2 handled them quite well. It made an articulated platform jack with a very smooth action and the print-in-place mechanisms broke apart freely but there was a small amount of Z-shift and some sloppy bridging towards the top. The hollow cube didn't show much stringing or wobble but there were some slight sags in the bridges. We only printed these models in PLA, since we were struggling to get successful prints in ABS.

A pair of low-poly statues followed, with the Creality CR-10S Pro V2 continuing to do very well in PLA. These prints looked superb, with clean overhanging and small points that printed cleanly. The ABS version had a smooth finish as well but we again had plenty of layer separation.

Our next three evaluation prints were a single-layer spiral faceted vase, a tall tower to look for Z-axis wobble, and a model that is close to a capital “F” to test how a sacrificial support matrix worked. The spiral vase made by the Creality CR-10S Pro V2 came out perfect, with the tall tower being just a bit behind, having a minuscule amount of wobble if you ran your fingers along the edge. The support structure cleanly came off, leaving a fairly nice surface finish on the underside of the supported area. Again, we did these prints in PLA only since we were having so many layer separation issues.

Our last two test prints are a threaded jar and lid. The PLA print came out alright, with plenty of surface blemishes and cosmetic defects but did thread together quite easily.

The ABS jar had poor layer adhesion as well.

Ease of Use

Our next round of tests focused on how user-friendly and easy to operate each 3D printer is, which is responsible for 30% of the final score. We looked at how long it took to get the printer going out of the box, how much work it is to level the bed or swap filament, and how you can send files to the machine.

The Creality CR-10S Pro V2 has a ton of features that make it easier to use but it does take a little effort to get the printer set up out of the box. You need to attach the main gantry and level the X-axis, as well as plug some wires in.

Once you have it built, it's very easy to get the bed leveled using the automatic assistant to get it initially leveled. The touch probe will also measure the height of the bed in 25 places before each print as well to compensate for any minor differences. .

It isn't too much work to change the filament but the filament sensor can be a bit obnoxious to thread through. Files can be sent to the printer through a USB cable or a microSD card and it has a touchscreen that shows you the current progress of the print.

Print Capabilities

Our next round of tests dealt with what you can actually do with each printer, comprising 20% of the total score. We awarded points based on what slicing software you can use with each machine, their build volume and range of compatible plastics, and the type of build plate.

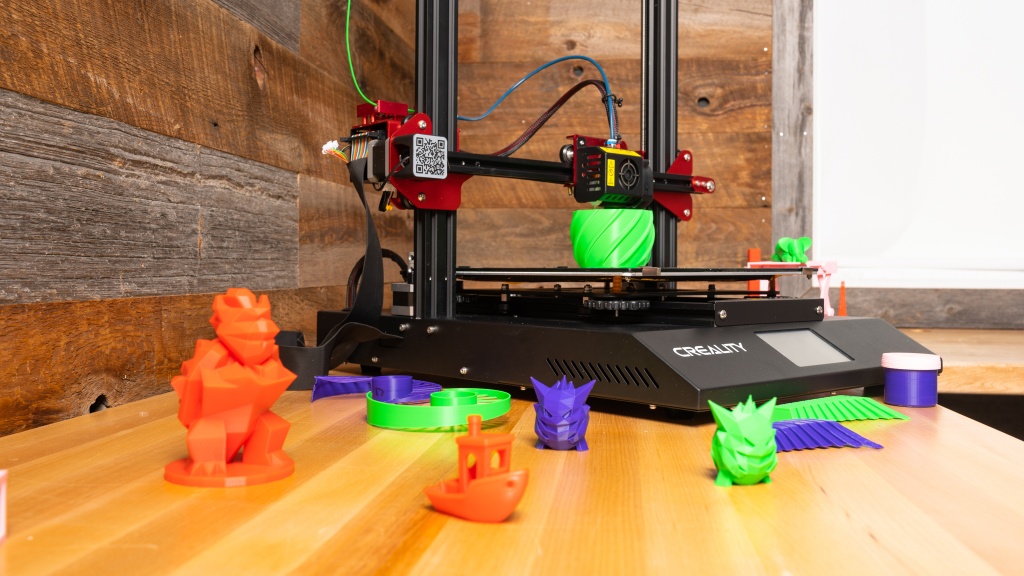

The Creality CR-10S Pro V2 has a large build volume measuring 300mm x 300mm x 400mm — usually enough to print a full-size helmet in one go if you are interested in making replica props or cosplaying. You aren't restricted to a proprietary filament, with any 1.75mm filament that doesn't require a higher temperature than 160°C. This is the maximum temperature the extruder can reach and the bed can reach a maximum temperature of 110°C.

It has both an extruder and layer fan and a build plate that seems pretty good, though we did have some persistent bed adhesion issues with ABS. 3D files can be sliced using Creality 3D's own slicer or any other of the common programs, like Simplify 3D or Cura.

Support

Our fourth and final metric dealt with the level and quality of customer support accompanying the Creality CR-10S Pro V2, which is responsible for the remaining 10% of the total score.

We have had mixed results with the support from Creality 3D, as they can be a little difficult to get in touch with through their contact form or email. They have been moderately helpful with our questions but we wouldn't count on them too much for support. However, there are tons and tons of third-party resources on this printer available online if you get stuck. We would just suggest you get the printer through a reputable source that allows you to return it if you get a damaged model. Creality 3D also stated this printer includes a 1-year warranty with a 30-day return at the time of writing.

Value

The Creality CR-10S Pro V2 is a fantastic value offering an excellent performance at a much more affordable price, making it one of our top recommendations for anyone looking for the most bang for the buck when it comes to 3D printers.

Conclusion

All in all, the Creality CR-10S Pro V2 is one of our all-time favorite machines. It has a large build area and a wide range of capabilities. It's very user-friendly and makes high-quality prints, all in a sleek and compact form factor.